portland cement raw mill operation

11.6 Portland Cement Manufacturing - U.S. Environmental

The portland cement manufacturing industry is relying increasingly on replacing virgin materials with waste materials or byproducts from other manufacturing operations, to

11.6 Portland Cement Manufacturing - US EPA

1971.8.17 The second step in portland cement manufacture is preparing the raw mix, or kiln feed, for the pyroprocessing operation. Raw material preparation includes a

Cement Plant Operation Handbook PDF Mill (Grinding)

Portland cement is manufactured in a series of processes which may be represented as shown: Limestone (calcium carbonate) and other materials containing appro- priate

Portland Cement Manufacturing – Ordinary Portland

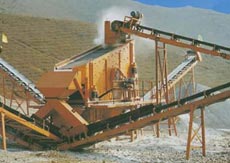

The Portland cement manufacturing process can be divided into 6 steps: raw material crushing, pre-homogenization, fine grinding, clinker production, cement grinding, cement packing, etc. In these processes, we need the

Cement mill - Wikipedia

Cement mill. A 10 MW cement mill, output 270 tonnes per hour. A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker

Portland cement - Wikipedia

Portland cement clinker is made by heating, in a cement kiln, a mixture of raw materials to a calcining temperature of above 600 °C (1,112 °F) and then a fusion temperature, which is about 1,450 °C (2,640 °F) for

Portland Cement Manufacturing Industry NESHAP Summary of

In-line kiln/raw mill means a system in a portland cement production process where a dry kiln system is integrated with the raw mill so that all or a portion of the kiln exhaust

Cement Manufacturing—Technology, Practice, and Development

2021.11.17 The primary cement manufacturing process involves the mining of raw materials, mainly limestone and clay, which are used in cement manufacturing. In most

eCFR :: 40 CFR Part 63 Subpart LLL -- National Emission Standards

In-line kiln/raw mill means a system in a portland cement production process where a dry kiln system is integrated with the raw mill so that all or a portion of the kiln exhaust

>> Next: Ligero De Arcilla Expandida Máquina Total

Artículos Relacionados

- doble tornillo alimentador

- mandíbula trituradora de carbón proveedor jakarta

- mineria la construccion de la mineria la produccion de polvo de talco

- pequenos precios molino de bolas experimento

- Venta de trituradora de cuarzo para minería tanzania en venta.

- mini trituradoras de piedra para la minería en méxico

- de flotacion de carbon beneficio equipos precio

- trituradoras de rodillos móviles usados

- molino proceso de refinacion de oro ppt

- molino de polvo fino

- de funcionamiento de una trituradora de hormigón

- trituradora de equipo de cribado y mineria

- tienda de molino de mano

- trituradora de minas de aridos

- gesso equipamentos de mineracao

- separador de tornillo para concentracion de mineral

- proyección de trituración móvil de mineral de hierro

- molino seco continuo de arena de sílice y feldespato

- instalação de linha de britagem

- clasificación en seco la máquina trituradora

- aplicaciones del molino de vibracion

- caracteristicas tecnicas de trituradora de pellets

- Lista De Equipos De La Cantera

- de la trituradora minera

- trituradora de la roca casera

- la fabricaci n de piezas para trituradora

- maquina s divisora de masa

- 4r3016 raymond molino de rodillos de bangke

- trituracion y molienda de los molinos en ee uu

- trituradoras forestales africa